In previous articles, we explored how pump seal failures occur and how Wechsler Technologies’ PumpGuard™ provides a multi-layered defense system to prevent them.

But while technology plays a vital role, preventive maintenance and disciplined operation are equally important. This article outlines key best practices that every plant using thermal fluid systems should follow to reduce risks and ensure consistent performance.

By combining predictive data with visual inspections, you minimize the risk of failure and downtime.

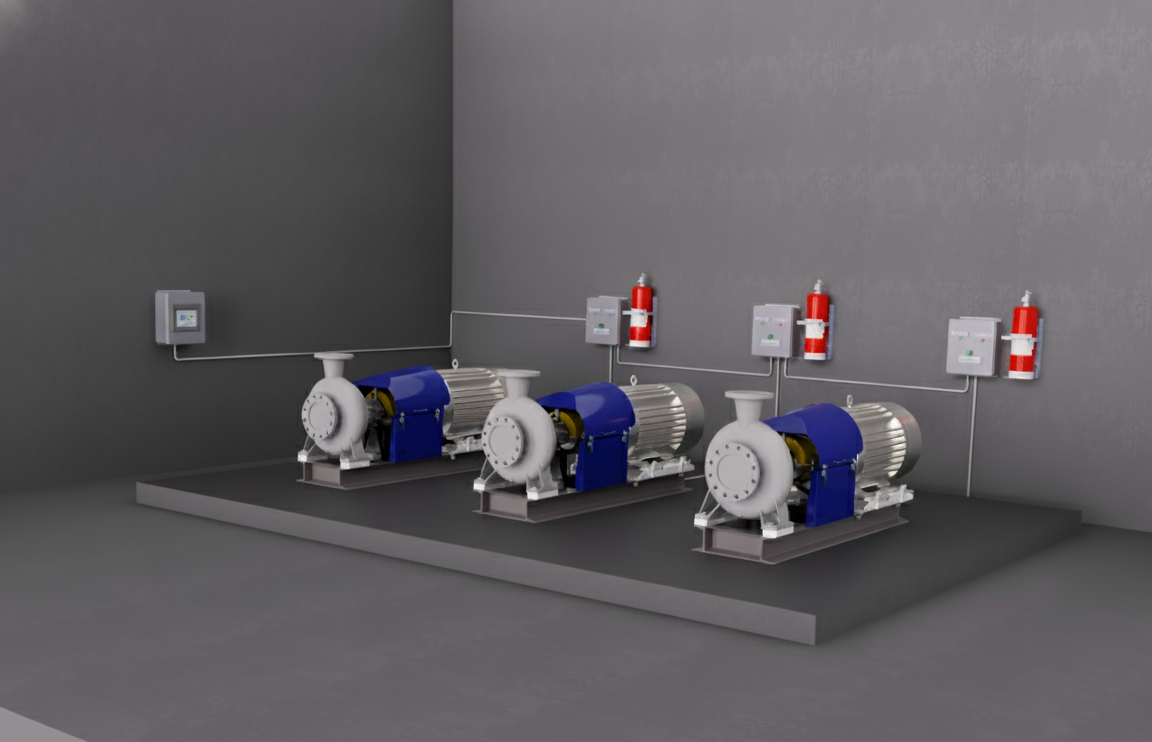

Relying solely on full-room fire suppression is insufficient. Localized protection at the pump level ensures faster containment and minimal collateral damage. Installing localized suppression systems—like those in PumpGuard—targets the ignition point directly, limiting fire spread and cleanup costs. Learn more about PumpGuard’s localized suppression technology.

A strong safety program depends on standardized procedures and maintenance.

Even the best equipment requires disciplined usage to ensure long-term reliability.

Systems like PumpGuard’s Multi-Point Monitoring make this achievable across large plants without additional overhead.

Preventing pump seal failures requires both robust technology and operational discipline. By combining real-time monitoring, predictive maintenance, and localized suppression, plants can reduce downtime and improve worker safety.

Wechsler Technologies helps operators achieve these goals with end-to-end solutions like PumpGuard™, designed for reliability, safety, and reduced downtime.

How Leading Plants Use PumpGuard™ to Reduce Downtime and Improve Safety Learn more about PumpGuard on the product page, explore our technical insights, or speak with a Wechsler Technologies expert to assess how PumpGuard can be tailored for your facility.

Copyright © 2025 Wechsler Technologie’s. All Rights Reserved.