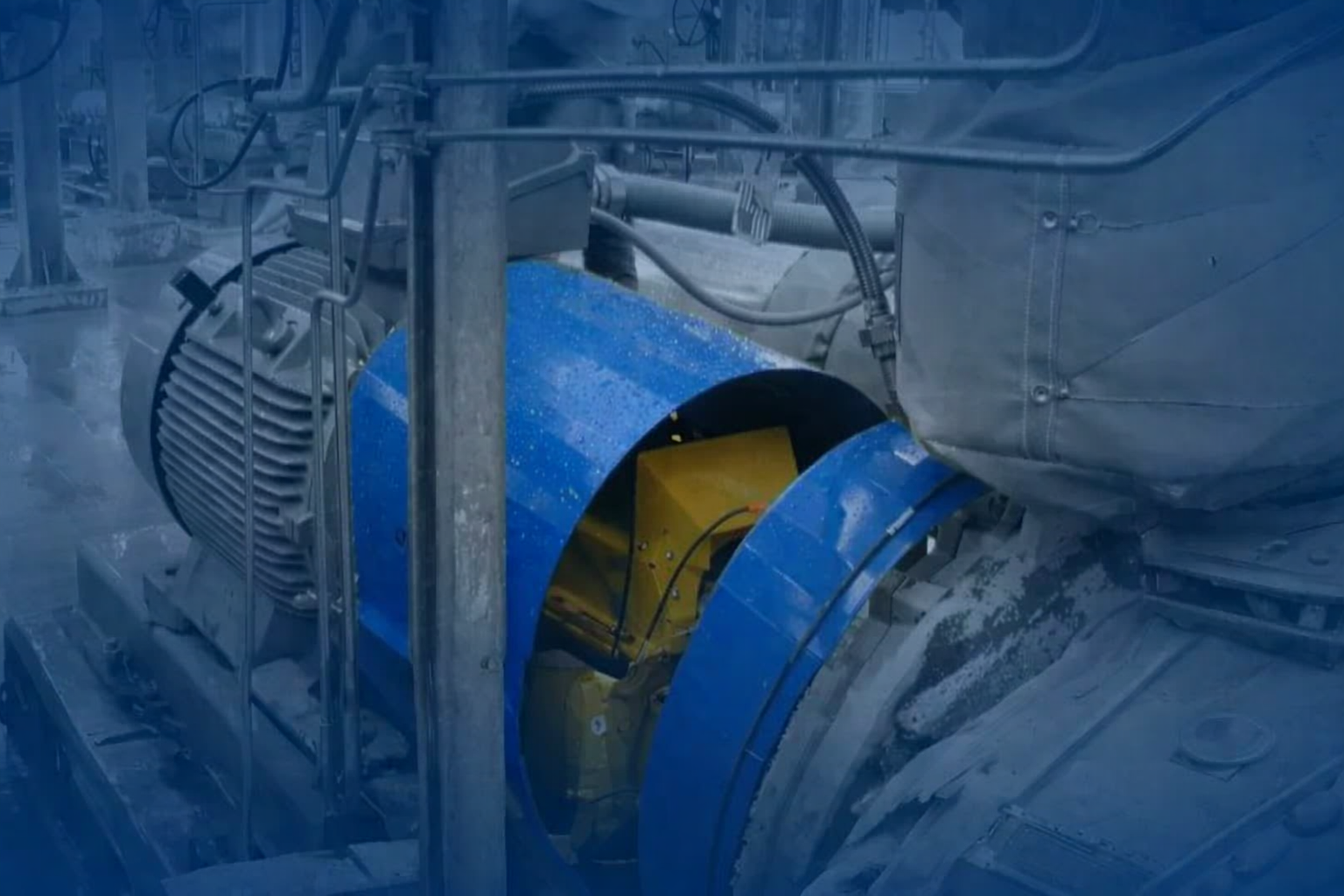

In thermal oil systems, pumps play a crucial role in circulating heat transfer fluid, which enables production across various industries, including engineered wood manufacturing, chemical processing, food production, and industrial materials. When these pumps operate reliably, heat is delivered safely and consistently throughout the process.

However, when pump seal failures are ignored, the consequences can escalate quickly and with little warning. Mechanical seal degradation rarely begins as a dramatic failure. Instead, it develops gradually through heat exposure, vibration, and material wear. When early warning signs go unnoticed, what starts as a minor seal issue can progress into thermal oil leakage, localized ignition, unplanned shutdowns, and extended downtime.

Understanding what happens when pump seal failures are overlooked is essential for improving safety, protecting equipment, and maintaining operational continuity in thermal oil systems.

Mechanical seals are designed to prevent hot thermal oil from escaping where the pump shaft passes through the casing. In thermal oil applications, these seals operate under demanding conditions:

Unlike lower-temperature fluid systems, thermal oil systems often operate close to the fluid’s flashpoint. This makes seal integrity especially critical. Even small leaks can present a serious fire risk when hot oil is exposed to oxygen near rotating equipment or other ignition sources.

Despite this risk, pump seals are often treated as routine maintenance items rather than critical safety components.

Pump seal failures typically follow a predictable progression rather than occurring suddenly. Common contributors include:

Industry experience and NFPA guidance consistently identify pump seals as one of the most common ignition points in thermal oil systems. Once ignition occurs, fires can spread rapidly, triggering emergency shutdowns and activating full-room fire suppression systems—often after damage has already occurred.

Many facilities rely on periodic inspections or operator observation to assess pump condition. While these practices have value, they cannot provide continuous insight into seal health.

Localized pump-level fire protection can:

Many plants work with Wechsler Technologies to evaluate pump-level fire risk and determine whether localized fire protection is appropriate for their thermal oil systems.

Ignoring pump seal degradation leaves a critical safety gap in thermal oil systems. While full-room fire suppression systems remain important, they are not designed to address the earliest stages of seal failure—when prevention is still possible.

Modern thermal oil operations are increasingly focusing on localized, preventive fire protection at the pump, where most ignition events originate.

Wechsler Technologies focuses on pump-level preventive fire protection to help reduce fire risk in thermal oil systems before incidents occur. Our solutions are designed to identify early warning signs, support safer operations, and minimize unplanned downtime caused by pump seal failures. For expert guidance and preventive protection solutions, contact Wechsler Technologies at info@wechslertech.com or +4042630934

Copyright © 2025 Wechsler Technologie’s. All Rights Reserved.